Dedicated to attain an

unrivaled position in domestic market through

an uncompromising commitment towards quality of coal gasifier and other products, Urja Thermal Solutions is regarded as one of

the most trusted companies to conduct business with. We are a well known manufacturer, exporter and supplier of various Gas Producer Plants and Vertical Shaft Kilns. Our comprehensive product range comprises Biomass Gasifiers, Industrial Biomass Gasifiers, Coal Gasifiers, Producer Gas Burners, Gas Cleaning Systems, and more. Apart from this, we are also engaged in Process Automation of Chemical Plants, Ceramic Plants and Allied Equipment. Further, keeping in mind the needs of our vast clientele, we have also engaged ourselves as a service provider for Planning, Commissioning, and Erection of our range of Plants. Till date, we have installed more than 70 Biomass Gasifiers, Industrial Biomass Gasifiers and Coal Gasifier all over India.

|

|

We are reputed biomass gasifier suppliers, having the support of a robust and hi-tech manufacturing unit managed by an experienced and well-trained team of professionals. With their ongoing service assistance, they help us come up with highly functional Gas Producer Plants as per needs of our clients. We are recognized as biomass gasifier, Industrial Biomass Gasifiers and Coal Gasifiers and are empowered by our endeavor of undertaking continuous research activities, which facilitates product innovation in line with emerging market trends. Besides, we hold fast to a cardinal business objective that entails us to provide technologically-advanced products and tailor-made services that are efficient, prompt and highly cost-effective to our valued clients.

Application Areas

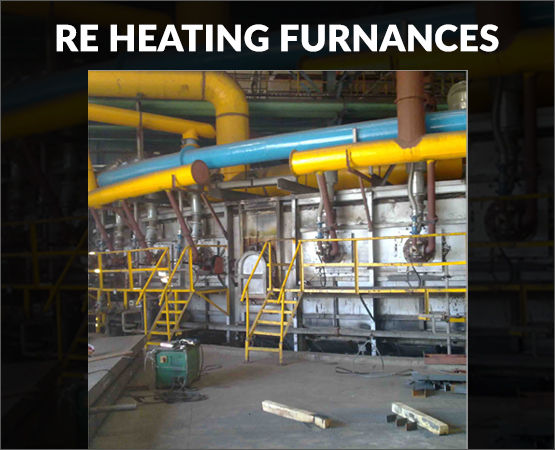

- Reheating Furnaces

- Ceramic Kilns

- Aluminium melting industries

- Sponge iron-dri rotary kiln

- Iron ore pellet plant

- Lime calcinations plants

- Sodium silicate plant

- Glass industries

- Sugar mill

- Paper mill

- Boiler industries

- Fertilizer

- Forging industries

- Annealing kilns

- Hot air generator

- Mineral processing

- Oven & Furnaces

- Biscuit Kilns

- Glaze Kilns

- Roller Kilns

- Rotary Kilns

- SOP Furnaces

-

Pinch Roller -

Producer Gas Fired Burner -

Gas Producer Plants -

Hot Air Generators -

Reheating Furnaces -

Biomass Gasifier -

Ladle Preheater -

Vertical Shaft Kiln -

Beam Type Reheating Furnace -

Electrostatic Tar Precipitator -

Furnace Oil Fired Burner -

Butterfly Valves -

Coal Gasifiers -

Actuator Servo Valve -

Industrial Recuperator -

Pusher Type Reheating Furnace -

Dual Fuel Burner

|

URJA THERMAL SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |